Contact with

us for any

soluton

Call Anytime

+91 99253 11003

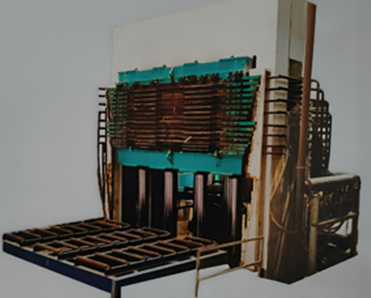

Plywood Hot Press

Plywood hot press machines are crucial industrial equipment used in the manufacturing of plywood sheets. These machines apply heat and pressure to layers of wood veneers glued together with adhesives, such as phenol-formaldehyde resin, to create strong and durable plywood panels. Typically, plywood hot presses consist of a robust steel frame that houses hydraulic or pneumatic systems responsible for applying uniform pressure across the entire surface area of the plywood stack. Heat is generated either through steam or electrical heating elements integrated into the press plates, ensuring optimal bonding of the veneer layers.

Plywood hot press machines use precise heat and pressure control to ensure optimal bonding strength between wood veneers, enhancing the durability and reliability of the plywood sheets produced.

These machines are versatile, capable of producing plywood sheets of varying sizes and thicknesses to meet the specific requirements of industries such as construction, furniture manufacturing, and interior design.

Modern plywood hot presses offer advanced features such as automated temperature and pressure controls, ensuring precise manufacturing specifications are met consistently. They are designed to handle various sizes and thicknesses of plywood sheets, catering to the diverse needs of furniture manufacturing, construction, and other industries requiring high-quality plywood products.

• Door-UF/PF, Blockboard, Decorative Vennear even Plywood

• All Glue PF/UF/D3/PUR/HOT MELT for Door & Flush Door & Block Board & Plywood

• Moulded Door Without Plate, Malamine Skin Door

• Solid Window Frame Tested At 300 Kg / Cm Pressure

• Tested With Paper Test • Solid Drilled 8′ • Ground Platen • Least temp Variation

• All Glue PF/UF/D3/PUR/HOT MELT for Door & Flush Door & Block Board & Plywood

• Moulded Door Without Plate, Malamine Skin Door

• Solid Window Frame Tested At 300 Kg / Cm Pressure

• Tested With Paper Test • Solid Drilled 8′ • Ground Platen • Least temp Variation

Benefits of Designing

Advanced Plywood Hot Press Machines

Consistent bonding strength.

Reduced manufacturing costs.

Intuitive operation controls.

Versatile production capabilities.

| Type Of Press | H-Frame Press |

|---|---|

| Press Platen Dimensions | 2500 × 1300 x 45 mm |

| Max. Working Pressure | 200 kg. / cm? |

| Gap of Platen | 80 mm |

| Cylinder | 200 mm |

| Heating Medium | Thermic Fluid |

| Power | 25 HP |

What is a plywood hot press machine?

It's a machine that uses heat and pressure to bond wood veneers into plywood sheets.

How does a plywood hot press work?

It applies heat and pressure to layers of wood veneers glued together with adhesive, forming plywood.

What are plywood hot presses used for?

They're used in industries like construction and furniture to produce strong and durable plywood panels.

What types of adhesive are used in plywood hot presses?

Common adhesives include phenol-formaldehyde resin for strong bonds in varying conditions.

What are the key components of a plywood hot press machine?

They typically include a steel frame, hydraulic or pneumatic systems, and heating elements.

What sizes of plywood can be produced with these machines?

They can produce plywood sheets in various sizes and thicknesses to meet specific requirements.