Contact with

us for any

soluton

Call Anytime

+91 99253 11003

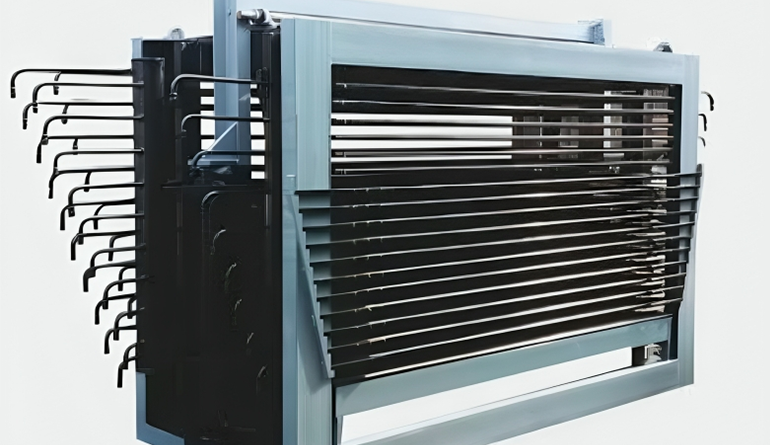

Core Dry Press

A core dry press is a vital industrial machine used primarily in the manufacturing of plywood and composite materials. It is designed to dry and compress the core veneers or materials, ensuring uniformity and enhancing the overall quality and durability of the finished product. The machine applies heat and pressure to the core materials, effectively reducing moisture content and consolidating layers for optimal bonding. This process not only improves the structural integrity of the products but also increases production efficiency by reducing drying times and minimizing material wastage.

The Core Dry Press offers rapid drying and compression, enhancing production speed and product uniformity.

Its advanced technology ensures energy-efficient operation, reducing costs and environmental impact.

Its robust construction and user-friendly interface make it easy to operate and maintain, while its automated functions enhance productivity and reduce the need for manual intervention. Key specifications typically include adjustable pressure settings, temperature control, and a range of sizes to accommodate different production needs.

Benefits of Designing

Experience the Ultimate in Core Dry Press Technology

Faster drying times.

Uniform moisture removal.

Reduced energy consumption.

Improved core strength.

| Type Of Press | H-Frame Press |

|---|---|

| Model | SI9X4X18 |

| Feeding Direction | HORIZONTAL |

| Feeding Space | 65MM |

| Numbers of Hot Plate | 19 NOS. |

| Layers | 18 |

| Plate Size | 2800 X 1330 MM |

| Nos. of Cylinders | 4 NOS. 90 MM |

| Max Pressure | 60 PSI |

| Working Temp | 120 C TO 140 C |

| Closing Time | 25 SEC. |

| Release Time | 20 SEC. |

| Process | AUTO |

| Max. Single Batch | 1155 SQ.FT. |

| Normally Drying Time | 30MINUTE @ 130 TEMP |

| Power | 5 HP |

| Over All Dimension | 4700 X 2700 MM |

| Approx Weight | 6800 KG. |

What is a Core Dry Press?

A Core Dry Press is a machine used in the plywood and veneer industry to dry core veneer sheets.

How does a Core Dry Press work?

It works by applying heat and pressure to remove moisture from the core veneer sheets, ensuring uniform drying.

What are the benefits of using a Core Dry Press?

It enhances the quality of the final product, reduces drying time, and improves production efficiency.

Can a Core Dry Press handle different sizes of veneer sheets?

Yes, Core Dry Presses can be adjusted to accommodate various sizes of veneer sheets.

What maintenance is required for a Core Dry Press?

Regular cleaning, lubrication, and inspection of components are essential for optimal performance.

Where can I purchase a Core Dry Press?

Core Dry Presses can be purchased from industrial machinery suppliers and manufacturers specializing in veneer and plywood equipment.