Contact with

us for any

soluton

Call Anytime

+91 99253 11003

Core Drying

Features PLC Controlled Electrical Panel. User Friendly and Maintenance Free. Available in 15 to 24 Daylight. Available in size 8’*4’, 9’*4’, 11’*4’ & 13’*4’. Ensure Better Straitening & Drying of Core. Lowest Power Consumption of 5 HP. Equal Lifting Equipment.

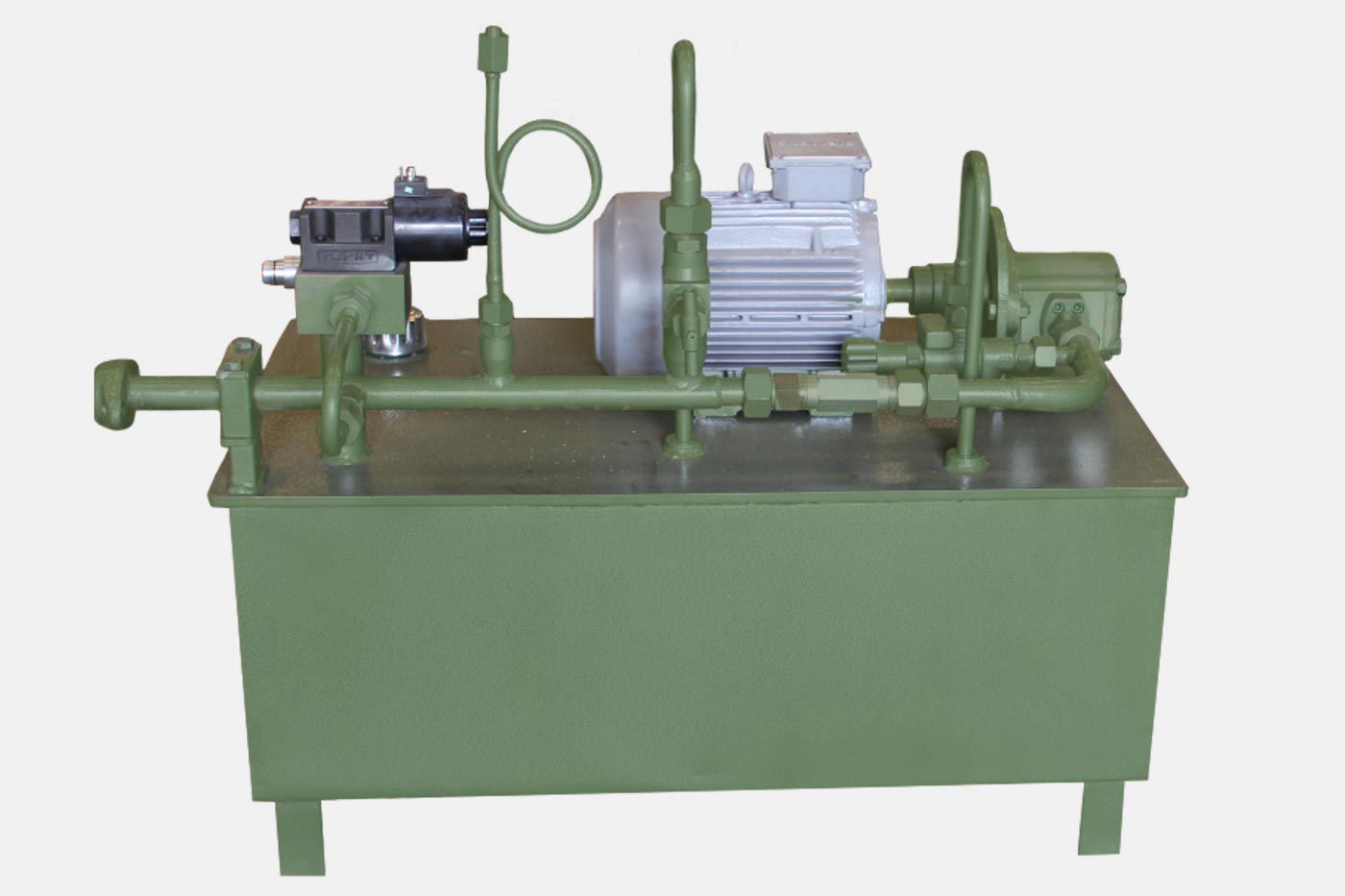

Some of the Specifications of the shown Press are as under:

Features

- PLC Controlled Electrical Panel

- User Friendly and Maintenance Free.

- Available in 15 to 24 Daylight.

- Available in size 8’*4’, 9’*4’, 11’*4’ & 13’*4’.

- Ensure Better Straitening & Drying of Core.

- Lowest Power Consumption of 5 HP.

- Equal Lifting Equipment.

Benefits of Designing

Speeds up the core drying process.

Ensures even moisture removal.

Reduces energy consumption.

Improves adhesive bonding.

What is core drying?

A process that removes moisture from plywood cores before further processing.

Why is core drying important?

It ensures even moisture levels, improving overall product quality.

How does core drying improve bonding?

Proper drying enhances adhesive performance by creating a better surface for bonding.

Does core drying reduce defects?

Yes, it minimizes issues like warping, cracking, and splitting.

Is core drying energy-efficient?

Modern designs focus on reducing energy consumption during the drying process.

What materials benefit from core drying?

Primarily plywood cores, but it can be applied to other wood products as well.